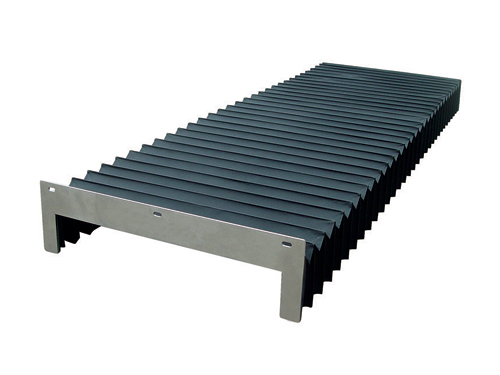

The processing flow of the guard cover for the organ

Organ shield shape rules, smooth surface, beautiful appearance, the overall shape of the machine tool add unlimited colors, and provide practical protection while also adding more visual beauty as the tool for your machine, the machine's overall value promotion.

The fixation of the organ shield on the mechanical equipment is very simple, and the accessories provided by the factory can be used. Under normal circumstances, according to the requirements of customers at both ends mounted with fixed metal connection skeleton or plastic connection skeleton. The slide property of the organ shield on the track can be improved by using a special slider. If the acceleration on the shield is relatively large, the same device can be used to make the machine shield have a uniform stretch.

One of the basic components of the organ shield is a PVC skeleton that supports a stable function in each fold. The framework can be connected with the external folding material through different processing methods.

One is thermal bonding. At a certain temperature, the inner PVC skeleton can be firmly bonded with the outer fold by means of special flux. If the shield is used in a moderate temperature environment, you can choose this way. This kind of thermal bonding shield does not need to be maintained, and it is waterproof, dustproof, oil resistant and acid resistant.

The other is sewing method, which is used in high temperature working environment. Sewing with a special thread, durable even under extreme loads. The PVC framework is sewn and fixed on each fold to reinforce the stable shield. At the same time, there are many materials for your choice. The shape stability of the shield is increased by using the internal support material, and the direct performance of this stability on the shield is to ensure that the initial shape can be restored

The processing flow of the guard cover for the organ:

1, is cutting material, the conventional use of cutting material is mainly three proofing cloth, this mainly according to the customer hungry demand, cut into the use of size, usually according to the customer to improve the size of the drawings to make specific production;

2, that is, stop sizing, after the completion of the size of the three proofing cloth began to finalize the stereotypes, this process is to maintain the main part of accuracy;

3, is to join the PVC board to do heat treatment, after this step, the shape of the protective cover basically can be said to be almost done;

4, is the shape processing, the three proofing cloth and PVC board as a whole processing, after this step is finished, even if the completion of the production;

5, is to complete the processing of organ type protective cover to do the performance test, see whether qualified.

Processing materials: flexible organ type protective cover on mechanical equipment fixed very simple, you can use the accessories provided by the manufacturer. Under normal circumstances, according to the requirements of customers at both ends mounted with fixed metal connection skeleton or plastic connection skeleton.

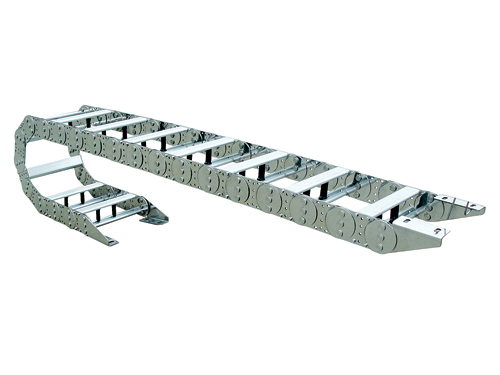

next:Structure and characteristic of steel drag chain